“Please do not use preserving agents and do not produce with ultra-high temperatures!”

That’s what retail and consumers are asking for. But natural germs can become a problem in those products. A ticking time bomb.

Expressions of thanks:

We would like to say thank you to BEN-CHRISTOPER WEITEMEYER, author of the actual study “Analyses of Heat-Treating of Black Pepper”, February 2015, graduate studies at University Bremerhaven, Germany. After finishing his graduation, Ben is now assistant manager of production.

Bacterial spores and germs exist in soil, water and dusty air. Already in the fields, germs from birds or microorganisms could affect. If Pepper is dried with contact to the soil, earth germs can multiply easily on the surface of the humid pepper corn.

Origin-related weather conditions with high temperatures, monsoon rain and humidity drive growths. If rainy season starts after harvesting, storing is getting difficult. Consequently, the germ load of pepper is relatively high.

| Spice | Bacterial count | Mould |

| Cloves | 0,2 – 33 | 0,01 – 0,1 |

| Ginger | 2,5 – 60 | 0,2 – 2,0 |

| Caraway | 2,0 – 9000 | 0,1 – 40 |

| Marjoram | 11,0 – 7600 | 0,3 – 2,5 |

| Nutmeg | 1,0 – 150 | 0,7 – 46 |

| Paprika hot | 41,0 – 12000 | 0,01 – 1200 |

| Pepper black | 10,0 – 700000 | 0,01 – 1300 |

| Cassia | 8,0 – 28000 | 0,1 – 60 |

| Germ count in 1000 germs per gram < | ||

Bacteria, Spores and heat-resistant Germs

Bacteria and mould are mainly on the surface of the pepper corn. Bacillus (Bacillus Cereus and Bacillus subtilis) are the most common. .

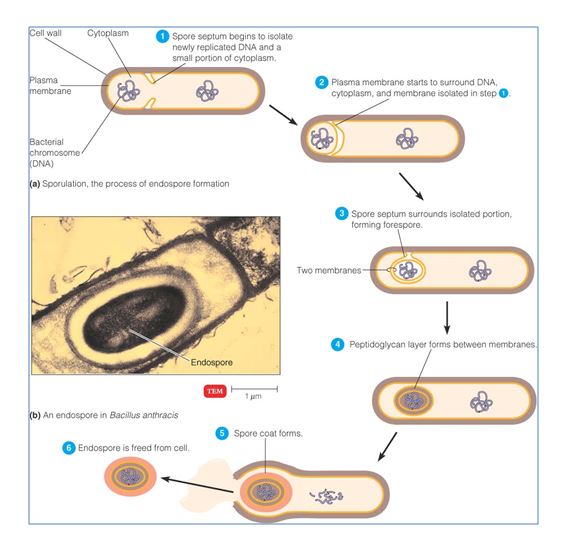

If bacteria suffer from deterioration of living conditions, i.e. by drying, bacteria build up spores. Those are resistant dormant bodies to survive for years in case of lack of nutrition, oxygen, heat or cold. They just can shut down their metabolism. They can survive for years as inactive cells. In the stomach of a 25 billion year old bee, survivable spores had been found!

Spores are produced inside of bacterial cells. They are well protected in the mother cell, form a protective casing and lose their water. Their heat resistance is rising. Later on, spores isolate from the mother cell and are independently existent.

Spores can – if reactivated – react mesophilic or thermophilic. Means: they can form multiple spores at humble temperatures between 20 and 45°Celsius (mesophil) or are activated by higher temperatures. (Thermophil) The kick-off of mould formation!

Black Pepper has mesophil aerobe germs count of 107 KBE/g. Thermo tolerant spores can account for up to 10 % of the entire spore population.

Strictly anaerobe spore formers (Clostridia) and non spore forming bacteria are rare. Mould is the second leading cause of contamination with an average germ load of 104 KBE/g.

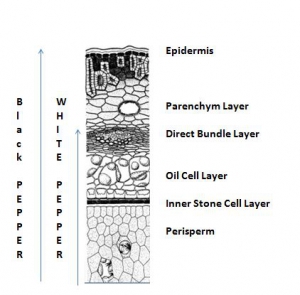

Cellular Layers of Pepper Corn

The proper process is of importance!

Europeans do not like ionized spices and microwaves capacities are rare, so germ reduction mainly takes place by steam-sterilizing. The principle: saturated steam is diffused on the pepper surface and kills or reduces germs.

The Permanent Process: Saturated steam is sprayed on spices whilst they are transported on conveyor belts. The open product heats up and will be cooled afterwards. The disadvantage of this process is: the product has to retain on the conveyor belts for some times. During that time thermo tolerants can be activated and risk of mould formation increases due to contact to oxygen, humidity and condensation. A very costly procedure, due to assets intenseness and product loss during the process of 3 % !

AKO/MESCH process:

Interesting and secure! This method of steam-sterilizing takes place in hermetically sealed chambers. The spices undergo the steam-treating process in their own packaging – which gives the advantage that no product losses take place. Additionally the packaging is steam-sterilized, too.

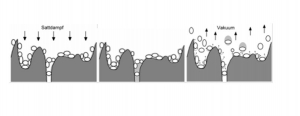

Heat, vacuum and steam treat the products in several intervals. Several kind of germs will be reduced Due to the changing phases of heat, vacuum and saturated steam, the detachments forces are more powerful than using the one-phase permanent process.

Every single step of process is adjustable – just to the needs. The intervals can be flexibly combined, to reduce mould, salmonella and mesophil germs.

Last but not least!

Normally endospores – thermophil germs – can survive and spore out (i.e. Bacillus lentus). But not within the AKO procedure: because within the “FLASH” (a rapidly decreasing temperature and pressure) cells will be properly evacuated and destroyed from the surface. To get those 10 % of germs, a high temperature and a long process time is needed.

AKO system: Treatment of termophile germs

Illustration: principle of heat-treating by using the “FLASH”. Left side: saturated steam is sprayed on the product. Middle: condense is growing on the surface of Pepper. Right Side: the sudden “FLASH” removes the cells from surface.

Taste & Security: all inclusive!

You do not see or taste it. Natural germ reduction of pepper is without influence to the organoleptic properties. Tests show: no loss of essential oils, no loss of taste!

Depending on process time and temperature, there might be some variations in humidity and density. Humidity increases by approx. 1 % in the final product.

The result of AKO’s heat-treating process is really good: very good microbiological results, death of spores and mould, safety with regard to salmonellas. (see table of results)

The physical principle of using vacuum, heat and steam, is not to be declared, effective and works without any product losses. This explains why pricing is so interesting.

AKO does not only heat-treat pepper, but a lot of other products. Just ask for it!

(All our information is based on our own knowledge and without engagement. We do not take any liability for that).