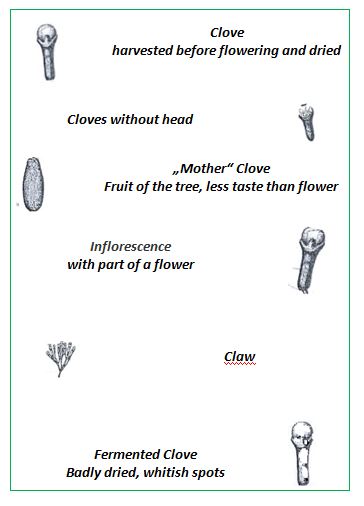

When we hear talking about quality, different parameters have to be regarded: cloves without head, immature or fermented ones, impurities or foreign matters. There are seven parameters for BAHIA Cloves to be regarded resulting in classifications as Types Bahia 1 – Bahia 4. In Madagascar the ethereal oil and humidity play a role when classified (CG1 – CG3). In Sri Lanka Qualities are classified into G1 to G3.

AKO The Spice Company! imports Cloves from Madagascar, purifies and sells them as whole Cloves because of their nice brown appearance. Sri Lankan Cloves are sold as grinded Cloves, because of their delicate flavor. Read more…

Never without…

Many rural workers or farmhands harvest them and let them sundry on the floor. Cloves are traded at many different stages from farmer to exporter. Only a few of the exporter dispose on modern machines to re-clean the material. Even “hand-picked” qualities bear a certain danger of impurities. Risk of contamination therefore is rather big. Thus cloves should only be sold after being re-cleaned in Europe.

Processing

It is not really „cleaning or washing“, it is more sorting out foreign bodies or plant specific parts by wind sifter, sieves, classifiers and detection of metals by magnets. There are many ways to do it:

Handpicking

Sorting our foreign matters by hand – mainly done in the Origin due to low labour costs.

Spiral cleaning

Using gravitation, means heavier and lighter materials are ejected by gravitation. In the end there is a lot of broken cloves. Foreign matters of same weight and size at the same time, cannot be sorted out.

Optical cleaning

This proceeding sorts out impurities of other colors. Drawback: machines are difficult to adjust. Only some sorts of those machines are reliably operating.

Optical Cleaner

seen in INDIA.

It is about the right processing

Our recleaning is multiple working, because of

- Windsifter, to sort out the fine parts in the material

- Two different sieves to sort out the bigger and smaller cloves

- Magnets to sort our metallic impurities

- And trieurs to sort out others.

With the use of a combination of different methods we can achieve a purity of about 98 %.

Raw Material upon arrival in Europe

Small and light parts blown out by wind-sifters

Small parts sorted out by sieves

Cloves after passing AKOs Re-Cleaning

Freshly grinded

Did you know? AKO is grinding whole cloves from Sri Lanka in our own German premises.

- To retain the value determine factors of the product as long as, Cloves are grinded in Germany to avoid a loss of ethereal oil during transport.

- To offer pure and non-adulterated goods und

- To maintain the high etherical oil level, we use a cold grinding process.

And after grinding: sieving is an obligation! All grinded material has to pass our 800 my sieves, before filled in bags. To have a ready to use product without any foreign matters! For sure.

You do not know our cloves already? Neither the nice brownish whole ones, nor the aromatic grinded ones? You should test them! Just ask for samples! We would like to surprise you.

In case of questions, please do not hesitate to contact us.

All data given are according to our todays knowledge or opinion. They are without obligation.